Description

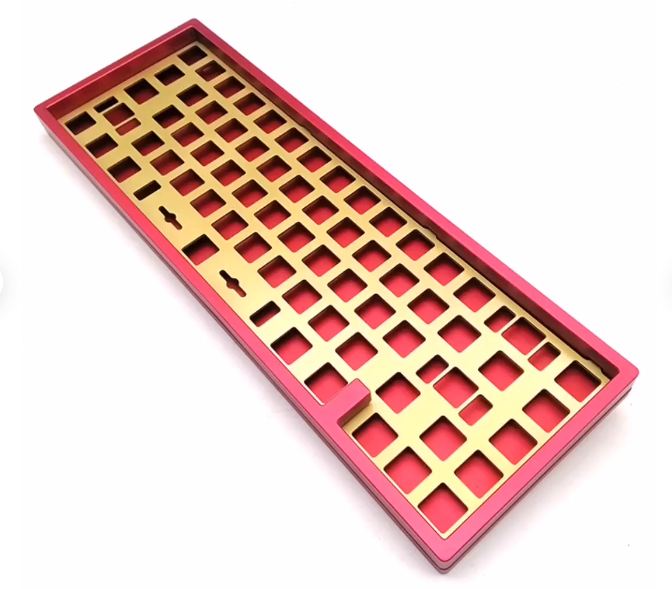

The features of a Custom CNC Keyboard Prototype Machining ISO Mounting 60% Brass Plate include:

1. CNC Machining: The plate is manufactured using Computer Numerical Control (CNC) machining, ensuring precise and accurate production for a high-quality end product.

2. Customization: The plate offers customization options, allowing users to tailor it to their specific requirements and preferences, such as choosing different layouts or adding custom features.

3. ISO Mounting: The plate is designed to support ISO layout keyboards, which feature an expanded Enter key and different positioning of keys compared to ANSI layout keyboards.

4. 60% Size: The plate follows the 60% size standard, which means it accommodates a compact layout with approximately 60% of the keys found on a full-sized keyboard. This site is popular among mechanical keyboard enthusiasts.

5. Brass Material: The plate is constructed from brass, which is known for its durability, rigidity, and corrosion resistance. Brass plates can provide a robust and premium feel to the keyboard.

6. Prototype Machining: The plate may be specifically developed for prototyping purposes, allowing for iterative design changes and testing before finalizing the keyboard layout.

7. Stable Mounting: The plate provides a stable and secure mounting surface for key switches, ensuring consistent and reliable performance during typing or gaming sessions.

8. Enhanced Typing Experience: The plate’s material and design may contribute to a unique typing experience, offering satisfying tactile feedback and reducing keyboard flex for improved stability.

9. Compatibility: The plate is compatible with a range of 60% mechanical keyboards, enabling easy integration into compatible keyboard cases and PCBs.

10. Aesthetic Appeal: The brass material of the plate can add a touch of elegance and sophistication to the overall appearance of the keyboard, enhancing its visual appeal.

Details

-Material: Aluminum 6063/Brass/Stainless Steel

-Surface Treatment: Sandblasted Grib from 80# to 180#/Anodizing any paton color/Polished/E-white/Coated clear/Brushed/Polished

-Available format: igs/.stp/.x_t/.step/.prt/.stl/.sldprt/.dwg/.dxf

-Tolerance: +/-0.01mm to +/-0.05mm