-

Die casting is a highly precise manufacturing process that transforms raw materials into intricate, durable metal components. In today’s competitive industrial landscape, the quality control process is not just a procedural checkpoint but the backbone of efficiency, safety, and consistency throughout production. In a die casting workshop, meticulous oversight—from the initial melting of the alloy to the final production inspection—is crucial in preventing defects, reducing waste, and assuring that each piece meets or exceeds stringent quality standards. This article delves into th......

2025.4.17Published by @WCYRead More -

Staying competitive requires innovative approaches to product development, and this is where rapid prototyping combined with CNC machining becomes indispensable. This combination accelerates the creation of custom robotic components, ensuring they meet the highest standards of quality and performance. In this guide, we will explore the importance of rapid prototyping, robot prototypes, the process of CNC machining for rapid prototyping, and how to select materials and parameters for robot manufacturing. The Importance of Rapid Prototyping in Robotic Manufacturing Speed and Cos......

2025.2.21Published by @LJCRead More -

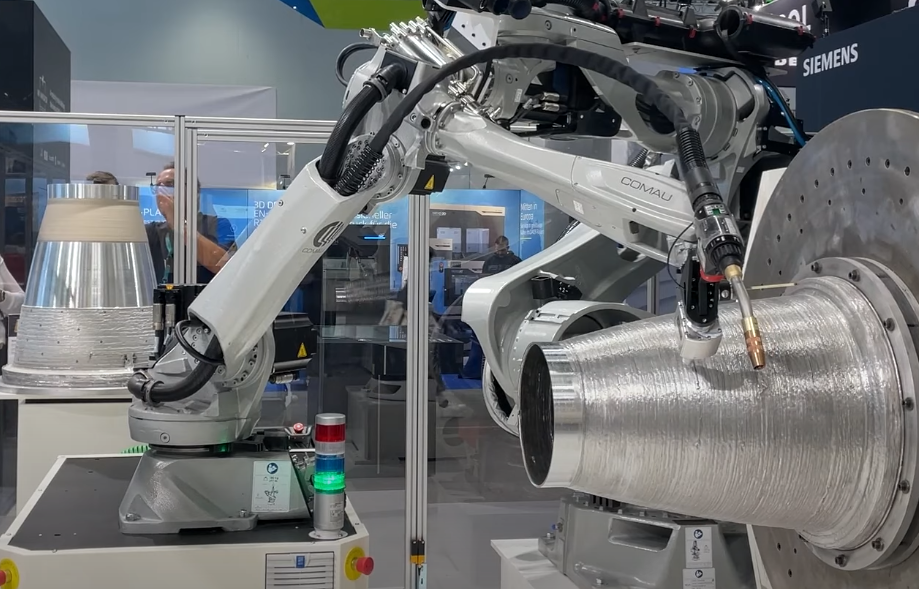

The evolution of manufacturing is driving the need for more efficient, precise, and adaptable production methods. Hybrid manufacturing, which combines CNC machining with additive manufacturing (AM), is emerging as a key approach for producing next-generation robotic components. This method integrates the accuracy of subtractive machining with the flexibility of additive techniques, enabling engineers to design and manufacture parts that are lighter, stronger, and more complex. According to Wohlers Report 2023, the hybrid manufacturing market is growing at an annual rate of 22%, with ......

2025.2.21Published by YLRead More -

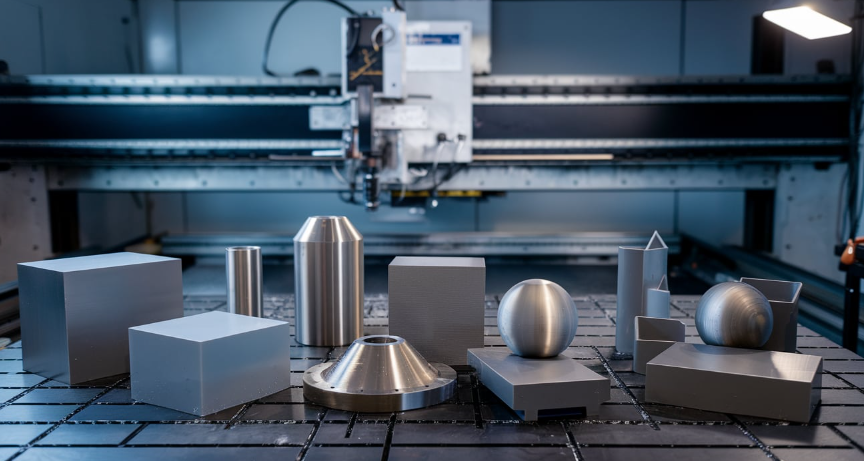

The demand for high-quality custom precision parts is increasing as industries such as aerospace, medical, automotive, and electronics require components that meet strict tolerances and deliver consistent performance. CNC (Computer Numerical Control) precision machining has become the preferred manufacturing method for producing these parts due to its accuracy, efficiency, and ability to handle complex designs. Today, we will examine why CNC precision machining is the ideal choice for creating custom precision components. What Is CNC Precision Machining? CNC precision mach......

2025.2.13Published by YLRead More -

CNC machining is a highly versatile manufacturing technique that delivers precision and consistency across various applications. However, costs can rise quickly if not managed properly. For engineers, designers, and business owners, knowing how to calculate and control CNC machining expenses is vital for remaining competitive. CNCJY.COM has been dedicated to providing customers with cost-effective CNC machining solutions for many years. Today, we will discuss how to calculate CNC machining costs for your project and share practical strategies to reduce expenses while maintaining quality......

2025.1.14Published by YLRead More -

The right material is crucial for getting the optimal performance of the fabricated parts and products. In this article, we’ll explore various factors influencing material selection and how to choose the best material for CNC machining. CNC Machining Material Selection Guide Material selection for CNC machining is a multifaceted process that requires careful consideration of various factors, including cost, applications, material properties, requirements, environmental factors, and more. CNC Machining (Material) Cost The cost incurred during the CNC machining process has......

2025.1.14Published by @LJCRead More -

In an era where manufacturing precision can mean the difference between market leadership and obsolescence, precision machining has emerged as the defining force behind industrial innovation and quality control. As we navigate through 2025, this technological cornerstone continues to reshape manufacturing landscapes across industries, from aerospace components measuring mere microns to medical devices requiring unparalleled accuracy. The evolution of precision machining represents more than just technological advancement—it embodies a fundamental shift in how we approach manufacturing c......

2025.1.10Published by @WCYRead More -

In the rapidly evolving manufacturing industry, custom CNC (Computer Numerical Control) machining stands as a cornerstone of industrial innovation. This sophisticated process combines advanced computer programming with precision machinery to transform raw materials into highly specialized components, it enables breakthroughs across numerous industries. Let’s understand the features and applications of custom CNC machining and how it impacts industry innovation and facilitates technological advancement. What Is Custom CNC Machining? Custom CNC machining plays a significan......

2025.1.3Published by @LJCRead More