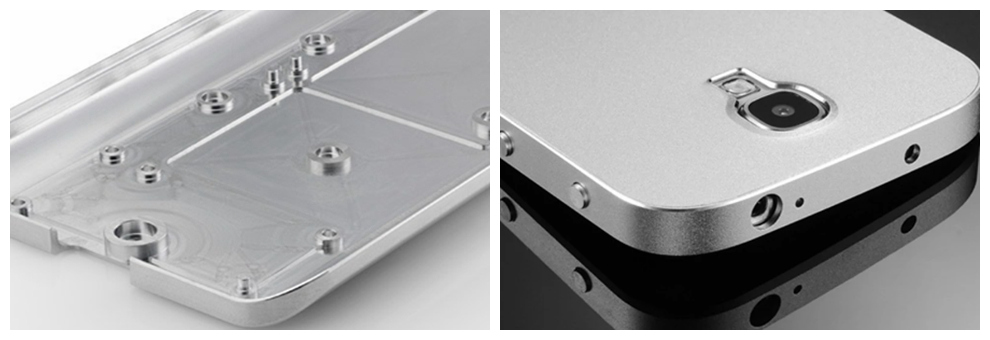

Most of the Apple or Huawei mobile phones we use every day are packaged in metal casings, so they will look very textured when people use them. And this kind of metal shell is aluminum alloy, which is smooth and bright like a mirror, and whether it is black, purple, white or other colors, it is all made of aluminum alloy dyed. An important process for making aluminum alloys have these characteristics is – anodizing. The metal casings of the mobile phones we use have all undergone anodic oxidation, so what are the advantages and characteristics of anodic oxidation?

Anodizing of aluminum profiles is a kind of electrolytic oxidation, in which aluminum and its alloys form a layer of oxide film on aluminum products (anode) under the action of external current under the corresponding electrolyte and specific process conditions. The oxide film transformed on the surface of the aluminum profile has protective, decorative and other functions. The ultimate goal of anodizing is also to obtain this layer of porous, dense, flat and uniform oxide film, which provides the basic conditions for subsequent aluminum alloy dyeing.

Characteristics of Aluminum Profile Anodized Film:

1. The structure of the oxide film is a porous honeycomb structure. The porosity of the film makes it have a good adsorption capacity. It can be used as the bottom layer of the coating and can also be dyed to improve the decorative effect of the metal. However, it is necessary to confirm whether the opening and closing of the membrane pores is good, otherwise the dyeing effect may be affected. If necessary, ht400 surface regulator can be used to open the membrane pores.

2. The hardness of the oxide film is high, the hardness of the anodic oxide film is very high, because the high hardness determines the wear resistance of the oxide film is very good.

3. The bonding force of the oxide film – the bonding force of the oxide film to the base metal is very strong, it is difficult to separate them by mechanical means, even if the film layer is bent with the metal, the film layer still maintains a good bond with the base metal .

4. Corrosion resistance of oxide film, Aluminum oxide film is very stable in air and soil, and has a strong binding force with the substrate. Generally, it will be dyed and sealed or sprayed after oxidation to make it corrosion resistant. Sex is further enhanced.

5. Insulation of the anodic oxide film, the impedance of the anodic oxide film of aluminum is high, the thermal conductivity is also very low, and the thermal stability can be as high as 1500 degrees.

Therefore, anodizing can finally make the aluminum alloy have the effects of dyeing, not easy to fade, wear resistance, corrosion resistance, and heat insulation. Of course, first of all, it is necessary to confirm the process and whether the oxide film is qualified. Open it, and then proceed to the subsequent dyeing, otherwise bad problems may really occur. It is precisely because of these characteristics that many mobile phones with aluminum alloy metal casings are inseparable from anodizing.