Many people believe that customized mechanical keyboards have different designs in different styles, but their structures are interconnected and cannot be separated from their roots. This article will briefly introduce the structure and special design of a mechanical keyboard.

Structure of Mechanical Keyboard

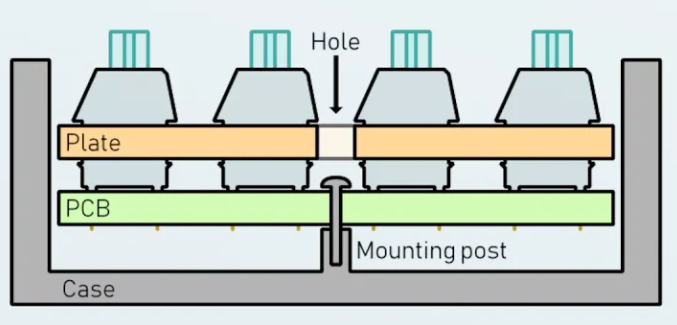

The structure of customized keyboards is divided into two categories: Case mount and Tray mount, and the design is divided into Plate and Plateless. Case mount is to fix the positioning plate and PCB onto the housing. The Tray mount is fixed to the bottom plate of the bottom shell. Plate is a design with a positioning plate, and Plateless is often referred to as “no steel”, without a positioning plate. Most Case Mount and Trail Mount devices connect the positioning plate and housing through screws.

Tray Mount

Track mount is a very simple and versatile structure. The keyboard has no upper or lower shell, and generally consists of a bottom shell+PCB+positioning plate. The bottom plate of the keyboard housing has screw holes that penetrate the positioning plate and PCB to secure the entire keyboard. The PCB, the positioning board, and the housing need to share the same screw positions to fit together. GH60 is the most famous Tray mount specification and is now commonly referred to as the “standard 60 column”. Any mass produced 60 keyboard will be compatible with the screw hole positions of GH60, with at least three screws shared. For example, Poker, Anne, and DC60. The first to introduce this installation method was the 60% keyboard of Vortex.

Advantages:

– Very low cost

– Very good compatibility (basically standard specifications, including outlet ports)

Disadvantages:

– Relatively unstable due to relatively few rigid/solid structures.

– Compared to the Case Mount kit, the overall rigid/solid structure is less and uneven, resulting in poor hand feel consistency.

– Due to the need for a certain height of the screw hole, the cavity sound will be relatively loud.

Case Mount

Case mount is a very robust, relatively high-end structure that directly secures the positioning plate and PCB to the housing. This installation structure is commonly used in relatively expensive mid/high-end kits.

Advantages:

– The inner liner and outer shell are firmly fixed and have a good hand feel consistency.

– There is no need to open a screw hole between the positioning board and the PCB for better wiring.

Disadvantages:

– The housing must be customized according to the situation (there are almost no specific standards).

– The material of the positioning plate has a significant impact on the typing experience.

Top Frame Mount

It is also known as top mount, refers to fixing the positioning plate to the upper cover. Common ones include Matrix 2.0 and OTD 360 series. This positioning plate has mounting tabs with screw holes that can be screwed onto the upper cover and then sequentially screwed onto the bottom box to complete keyboard assembly. This structure is widely used by high-end customized keyboards due to its excellent hand feel and relatively convenient processing.

Bottom Mount

Contrary to the Top mount, the inner liner is fixed to the bottom shell edge. This structure is a bit like a Track mount, but it is not fixed to the bottom shell, resulting in more and more uniform rigid structural support. At the same time, this structure does not require the participation of the upper cover, so it can be designed to have a suspended appearance. Personally, I think it will be slightly harder than Top Mount. Common ones include Matrix mona and Input Club White Fox More famous is the KMAC series.

Sandwich Mount

Firmly fix the positioning plate between the upper cover and the bottom shell. Sandwich mount is a much more complex fixing method than it sounds, because the positioning plate and the surrounding edge of the housing need to be closely fitted to ensure that the positioning can be perfectly centered while still having a little bending space for cushioning. Because the positioning plate is connected to both the top and bottom housings, a sandwich structured keyboard can better suppress bottom vibrations, making the bottom touch sound more peculiar and pleasing to the ear. The most famous design is the OTD 356 mini. There are also many high-end kits using this design, such as Cary Studio’s Verspa. CR (VCR) and TYL’s customized KN2.10

Integrated Mount

Integrated design of upper cover and positioning plate. Integrated mount does not have a replaceable positioning plate to match the color of the upper cover/lower shell. This is because the positioning plate and top shell are milled from the same aluminum/pc/titanium or whatever material. To achieve a texture similar to a sandwich structure. The positioning plate of the integrated mount continues to be constrained by surrounding elements. This can provide a hard bottom feel similar to a sandwich. Integrated mount is usually more dynamic. The cost is very low, and it is particularly easy to process.

Gasket Mount

With a gasket structure, screws only string up the housing, and a positioning plate is sandwiched between the two housings by pressure. The screws only string up the outer shell, and the inner liner has no rigid structure and screw support. It is completely pressed against the middle of the keyboard by rubber and upper and lower cover accuracy. “The feel will be very, very, very uniform, and due to the fixed rubber strips, there will be cushioning in both vertical directions, providing a warmer feel.”

Plateless Mount

Because this is a design, not a structure. It can be a Top mount, a Bottom mount, a Gasket mount, or even a Track mount The only difference between it and others is that it does not have a positioning plate. When pressing the shaft, it has a unique and elastic feel of knocking on the PCB. This design requires high PCB hole accuracy and generally does not support hot swapping. Otherwise, the shaft may be tilted or the shaft body may be pulled out by the roots when pulling out the key cap. After all, how can gentleman’s design allow such crude errors to occur?