Milling is a common manufacturing process in which a rotating tool removes material from a static workpiece and provides us with the required finish of the part. Vertical milling and horizontal milling are two common milling methods, which have unique operating characteristics, making them suitable for specific operations and applications. The difference between simple vertical milling and horizontal milling will be described below.

Horizontal Milling and Vertical Milling Guide

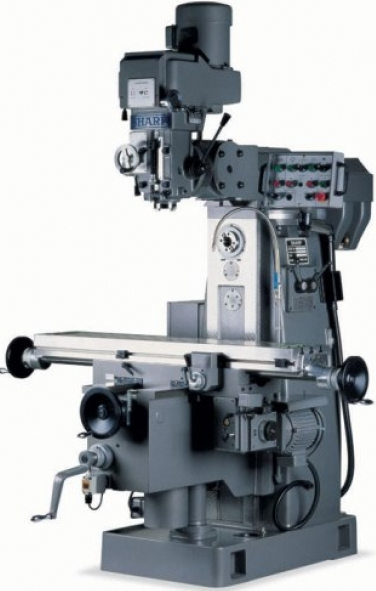

Milling machine is the standard equipment in mechanical workshop. They are used to remove material from stationary work pieces using mobile cutting tools. Different types of milling machines can better perform different types of work. Vertical milling is the processing method of vertical milling machine, which has a working surface on which materials are clamped. Then, use the cutting tool on the vertical moving spindle to remove the material from the workpiece, and shape it according to the work needs.

Horizontal milling is the processing method of horizontal milling machine, which is slightly different from vertical milling machine. The basic operation remains unchanged, however, the orientation of the tool will have a horizontal orientation. In general, horizontal milling is often used to process larger parts or deeper cutting, and the design and horizontal rotation of its processing tools result in higher cutting power and faster operation.

Differences Between Vertical Milling and Horizontal Milling

The main difference between vertical milling and horizontal milling is the orientation of the spindle of the milling machine. The direction of the spindle of the milling machine determines how the processing tool interacts with the workpiece. As their name implies, these two milling machines have different processing directions. The accuracy provided by vertical processing or horizontal processing can bring depth to the workbench.

The cutting specifications and accuracy of vertical milling and horizontal milling are also quite different. The geometric shape of the milling cutter has a direct impact on the cutting specifications and results. The vertical milling method is suitable for machining small parts. However, it also has parts that cannot be machined. For example, vertical milling will cause vibration during operation, which will lead to deviation between the part and the design, so it is impossible to use it to create deeper cuts. On the other hand, horizontal milling tools are shorter and thicker, which can make them bear resistance stably and produce deeper cutting.

Vertical milling and horizontal milling have more similarities than differences, but in general, vertical milling machines can provide a slightly wider range of operations. However, for larger workpieces and tougher metals, horizontal milling machines provide faster cutting speeds and greater power. From amateur garage to heavy equipment workshop, these two types of milling machines are very important parts of each machining workshop.

Which One To Choose, Vertical or Horizontal Milling?

Vertical milling and horizontal milling have their own advantages and disadvantages, but which one to choose depends on the manufacturing requirements. When selecting a milling machine, consider the type of work and budget you need to complete. In addition, the floor space and storage capacity of the workshop also need to be considered, because there is a large gap between the floor space and cost of horizontal milling machine equipment and vertical milling machine equipment.

When selecting vertical milling and horizontal milling, the machinist will first determine the type of cutting required, including their length and depth. Vertical milling uses longer and thinner tools for more accurate milling. Horizontal milling uses shorter and stronger tools to perform heavier, deeper or wider cuts, such as grooves for movable parts.

In addition, if you use the milling machine to complete daily tasks or long-term projects that require regular fast turnaround time, horizontal milling machine is the ideal choice. For projects with low time sensitivity, vertical milling machine is a good choice because it is simple to use and more affordable.

The article mainly introduces the difference between vertical milling and horizontal milling. Through browsing the article, we can know that the main difference between vertical milling and horizontal milling is the difference of the spindle orientation of the milling machine. The spindle orientation of the milling machine determines how the processing tool interacts with the workpiece. As their name implies, these two milling machines have different processing directions, and the accuracy or level setting provided by vertical processing can bring depth to the workbench.