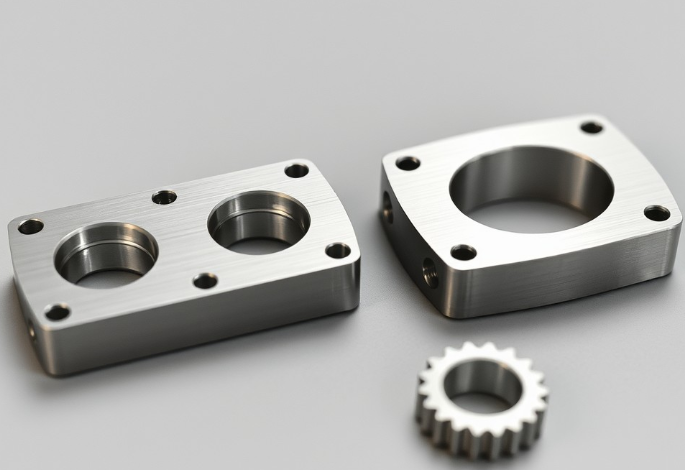

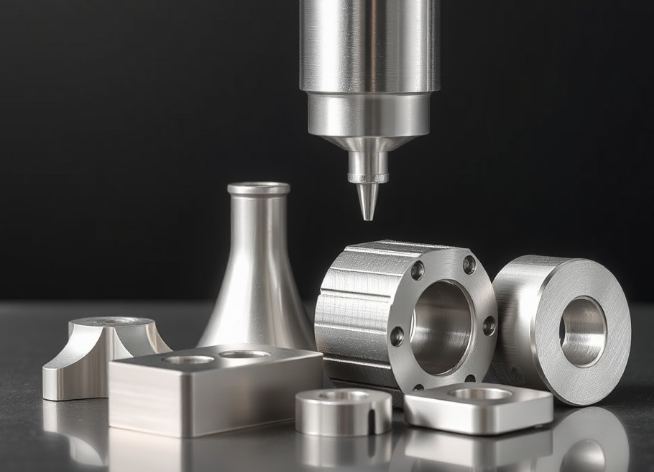

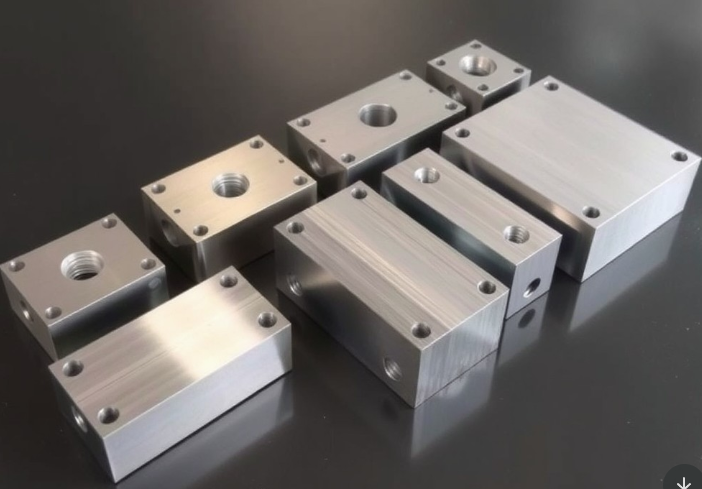

Aluminum CNC machining is a precise and versatile process used to create custom parts for industries like aerospace, automotive, and consumer electronics. By combining advanced technologies and refined techniques, this process ensures high-quality results. Below is an in-depth explanation of the steps and considerations involved in manufacturing aluminum parts through CNC machining.

Aluminum CNC Machining Process

1. Designing and Programming

The initial stage of CNC machining involves creating a digital blueprint of the part using CAD (Computer-Aided Design) software such as SolidWorks or AutoCAD. This 3D model must account for dimensions, tolerances, and the specific properties of aluminum. Once finalized, the design is converted into machine-readable G-code using CAM (Computer-Aided Manufacturing) software. This code dictates the toolpaths, machining operations, and cutting parameters, forming the basis for precision manufacturing.

2. Material Selection

Choosing the appropriate aluminum alloy is crucial. Aluminum grades such as 6061, 7075, and 5052 are commonly used due to their distinct properties like strength, corrosion resistance, and machinability. The choice depends on the specific application requirements. For instance, 7075 is preferred for aerospace components due to its high strength, while 6061 is versatile and widely used across industries.

3. Fixture Installation

To ensure stability during machining, the aluminum material is securely mounted onto the CNC machine using custom fixtures or vacuum suction cups. Proper fixation minimizes vibration, reduces deformation, and allows for precise cutting. For thin or irregularly shaped parts, specialized methods such as filling or axial clamping are employed to improve rigidity.

4. Rough Machining

During rough machining, excess material is removed to form the basic shape of the part. Tools with large cutting capabilities are employed for efficient material removal. This stage prioritizes speed and efficiency over precision, as it sets the foundation for subsequent operations.

5. Semi-Finishing and Finishing

In the semi-finishing stage, the dimensional accuracy and surface smoothness of the part are enhanced. Finishing follows, refining the part to its final specifications with tighter tolerances and superior surface quality. High-speed milling and down-milling techniques are often used to achieve these precise results, minimizing thermal effects and deformation.

6. Surface Treatments

Aluminum CNC parts often undergo additional surface treatments to improve functionality and aesthetics. Techniques like anodizing, polishing, and sandblasting are commonly applied. Anodizing, for instance, enhances corrosion resistance and allows for the addition of color, while polishing creates a high-gloss finish for a sleek appearance.

7. Quality Control and Post-Processing

Post-machining inspection is critical to ensure the part meets specifications. Tools like coordinate measuring machines (CMMs) and calipers are used for precise measurement. Secondary processes such as deburring or coating may also be performed to enhance the part’s usability.

8. Packaging and Delivery

After passing quality checks, the finished aluminum parts are carefully packaged to prevent damage during transport. Detailed documentation, including design files, machining parameters, and inspection reports, is maintained for traceability and quality assurance.

| Process Step | Description | Key Tools/Techniques | Considerations |

|---|---|---|---|

| Design & Programming | Creating a 3D CAD model and generating G-code for machining. | CAD/CAM software | Precision in design is essential. |

| Material Selection | Choosing the appropriate aluminum alloy. | Alloy grades (6061, 7075, etc.) | Depends on application and required properties. |

| Fixture Installation | Securing the material on the CNC machine. | Custom fixtures, vacuum clamps | Avoid movement and deformation. |

| Rough Machining | Removing excess material to create the basic shape. | High-speed cutters | Focus on efficiency, not precision. |

| Semi/Finishing | Enhancing dimensional accuracy and surface quality. | Down-milling, fine tools | Minimize heat and deformation. |

| Surface Treatments | Improving functionality and aesthetics. | Anodizing, polishing, sandblasting | Match surface properties to part requirements. |

| Quality Control | Inspecting dimensions and functionality. | CMM, calipers, inspection reports | Ensure tolerances and surface standards. |

| Packaging & Delivery | Ensuring safe transport and traceability. | Protective packaging | Prevent damage during shipment. |

The Different Aluminum Alloys Used in CNC Machining

Aluminum is one of the most widely used materials in CNC machining due to its unique properties and versatility. The selection of the appropriate aluminum alloy plays a crucial role in determining the performance, durability, and suitability of the final machined components. Here’s a closer look at the different types of aluminum alloys commonly employed in CNC machining:

6061 Aluminum Alloy

6061 aluminum is a popular choice for CNC machining, offering a balanced combination of strength, corrosion resistance, and machinability. It is commonly used in a wide range of applications, from automotive parts and aerospace components to industrial machinery and consumer products.7075 Aluminum Alloy

Known for its exceptional strength-to-weight ratio, 7075 aluminum alloy is often the preferred choice for high-stress applications, such as aircraft and military equipment. This alloy provides excellent tensile strength and hardness, making it well-suited for parts that require superior mechanical properties.2024 Aluminum Alloy

2024 aluminum alloy is prized for its high strength and fatigue resistance, making it a popular choice for structural components in the aerospace industry. It also exhibits good machinability, allowing for the creation of intricate and precise parts.5052 Aluminum Alloy

5052 aluminum alloy is renowned for its excellent corrosion resistance, making it an ideal choice for marine environments, outdoor applications, and components that require prolonged exposure to harsh conditions. It also offers good formability and moderate strength.6063 Aluminum Alloy

Characterized by its excellent surface finish and corrosion resistance, 6063 aluminum alloy is commonly used in architectural applications, such as window frames and door profiles. Its relatively low strength, however, makes it less suitable for high-stress components.1100 Aluminum Alloy

1100 aluminum alloy is a pure, commercially pure aluminum that offers excellent corrosion resistance, electrical and thermal conductivity, and workability. It is often used in applications where these properties are more important than high strength.

Surface Treatment Options for Aluminum CNC Machined Parts

Anodizing

Anodizing is one of the most popular and widely used surface treatments for aluminum. This electrochemical process creates a durable, protective oxide layer on the surface of the aluminum, improving its resistance to corrosion, wear, and abrasion. Anodizing can also be used to impart a wide range of decorative colors to the aluminum parts.Powder Coating

Powder coating is a dry finishing process that involves electrostatically applying a powdered paint-like material to the aluminum surface. This technique provides a uniform, scratch-resistant, and durable finish that can be customized in a variety of colors and textures.Painting and Lacquering

Painting and lacquering offer a cost-effective way to add color, protect the surface, and enhance the aesthetics of aluminum CNC machined parts. These liquid-based coatings can be applied using various methods, such as spraying or dipping, and can provide a smooth, glossy, or matte finish.Polishing

Polishing is a mechanical surface treatment that involves removing the outer layer of the aluminum to create a smooth, shiny, and reflective surface. This process can be carried out using different techniques, such as buffing, burnishing, or electropolishing, depending on the desired level of finish.Bead Blasting

Bead blasting, also known as shot peening, is a process that uses high-velocity air or centrifugal force to project small glass, ceramic, or metal beads onto the aluminum surface. This technique can create a uniform, matte or satin finish, and can also increase the surface hardness and fatigue life of the aluminum parts.Etching and Engraving

Etching and engraving are subtractive processes that remove material from the aluminum surface to create intricate designs, logos, or text. These methods can be used to add a unique visual element to the aluminum parts, enhancing their aesthetic appeal.Oxidation and Conversion Coatings

Oxidation and conversion coatings, such as chromate or phosphate treatments, can be applied to aluminum to create a thin, protective layer that improves corrosion resistance, paint adhesion, and electrical conductivity.

Common Challenges in Aluminum CNC Machining and Their Solutions

While aluminum is a widely used material in CNC machining, it presents its own set of unique challenges that require skilled operators and well-designed processes to overcome. Here are some of the common challenges in aluminum CNC machining and the solutions to address them:

Workpiece Deformation:

Challenge: Aluminum’s high thermal expansion and low rigidity can lead to deformation of the workpiece during the machining process, affecting the dimensional accuracy and surface finish of the final part.

Solution: Employ strategies like symmetrical processing, multi-layer machining, and optimized cutting parameters to minimize the cutting forces and thermal effects. Use clamping methods that distribute the holding force evenly, such as vacuum suction cups or specialized fixtures.Tool Wear and Chipping:

Challenge: The soft and gummy nature of aluminum can cause rapid tool wear, leading to increased production costs and compromised part quality.

Solution: Select cutting tools with the appropriate geometry, material, and coatings to improve tool life and chip evacuation. Optimize cutting speeds, feeds, and depths of cut to reduce heat generation and tool wear.Chip Removal and Buildup:

Challenge: Aluminum’s tendency to form long, stringy chips can lead to chip entanglement, tool clogging, and potential damage to the workpiece or machine components.

Solution: Incorporate chip breakers or chip crushers in the cutting tool design to promote the formation of short, manageable chips. Utilize high-pressure coolant systems to efficiently evacuate the chips from the cutting zone.Surface Finish Issues:

Challenge: Achieving a consistent, high-quality surface finish on aluminum parts can be challenging due to factors like tool wear, vibration, and the material’s inherent tendency to smear.

Solution: Implement strategies such as using sharp cutting tools, minimizing tool overhang, and optimizing spindle speeds and feed rates. Consider applying secondary finishing operations like polishing or buffing to enhance the final surface appearance.Residual Stresses and Part Distortion:

Challenge: The machining process can introduce residual stresses in the aluminum workpiece, leading to distortion or warping during or after the CNC operations.

Solution: Utilize pre-machining stress relief techniques, such as stress-relieving heat treatments or vibration treatments, to minimize the buildup of internal stresses. Adopt a multi-step machining approach with intermediate cooling periods to allow for stress relaxation.Machine Vibrations and Chatter:

Challenge: The low stiffness and high flexibility of aluminum parts can exacerbate machine vibrations, leading to poor surface quality, dimensional inaccuracies, and potential damage to the cutting tools and machine components.

Solution: Optimize the machining parameters, including spindle speed, feed rate, and depth of cut, to avoid resonance frequencies. Use high-performance toolholders, workholding devices, and machine tool components to enhance rigidity and dampen vibrations.