ABS generally refers to ABS plastic, which is a terpolymer of acrylonitrile (A), butadiene (B) and styrene (S). The relative content of the three monomers can be changed at will to make various resins. ABS has the common properties of three components. A makes it resistant to chemical corrosion and heat, and has a certain surface hardness. B makes it have high elasticity and toughness. S makes it have the processing and molding properties of thermoplastic plastics and improves electrical properties.

Therefore, ABS plastic is a “tough, hard and rigid” material with easy access to raw materials, good comprehensive performance, low price and wide use. ABS plastics have been widely used in machinery, electrical, textile, automobile, aircraft, ship and other manufacturing industries and chemical industry. ABS is a very common material for processing and making plastic handboards in the handboards industry. In the handboards model industry, ABS handboards are very much made. There are several ways to process ABS handboards: CNC machining, vacuum laminating, and 3D printing. What is the difference between these 3 ABS machining methods? What are their characteristics? Now we will give you a detailed introduction to the common ways of ABS plastic machining.

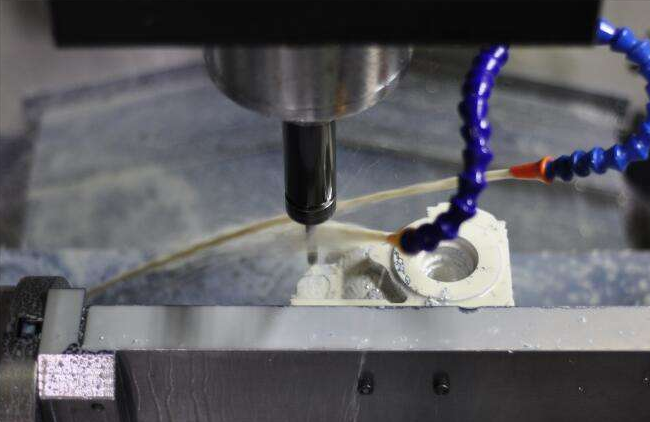

ABS Manual CNC Machining

1. Advantages: High precision, generally up to 0.05mm~0.1mm, and a wide range of processing dimensions. Some CNC machining centers can process a two meter long hand board as a whole. Various materials and good surface treatment effect.

2. Disadvantages: It is charged according to the working hours. For small and complex hand boards, it is not cost-effective to use CNC processing.

3. Features: High degree of automation, strong adaptability to CNC machining objects, high machining accuracy, stable quality, which can greatly improve machining accuracy, including machining quality accuracy and machining time error accuracy. The repeatability of the processing quality can stabilize the processing quality and keep the quality of the processed parts consistent.

ABS Hand Board 3D Printing CNC Machining

1. Advantages: High precision, fast printing speed, and complicated printing details.

2. Disadvantages: Charge according to weight, and the cost of printing large hand boards is high. Processing size is limited. There are few printing materials, mainly photosensitive resin and ABS.

3. Features: In the long run, the biggest feature of 3D printing is to save manpower, material resources and time costs. Because it can make the initial product very operable, we are not afraid to modify the work, but we are afraid of the time of repeated processing and transportation, which will waste too much cost in the next modification. Based on the characteristics of 3D printing, we can learn that 3D printing can complete models and finished products faster and better. The more expensive the device, the better the printing performance.

ABS Manual Vacuum Double Mold Processing

1. Advantages: Low cost, short production cycle, small batch (50-500 pieces) production has advantages.

2. Disadvantages: Due to the influence of thermal expansion and cold contraction of silicone liquid, the precision is relatively low, usually about 0.2mm. One set of silicone mold can only copy 10 handbooks, and the price is high when the quantity is more than 500.

3. Features: Low cost, short production cycle. There is less waste, and the processing cost is much lower than CNC machining and 3D printing. It is applicable to the processing and production of small batches of products, with good mold making operability, low probability of processing failure and good repeatability.