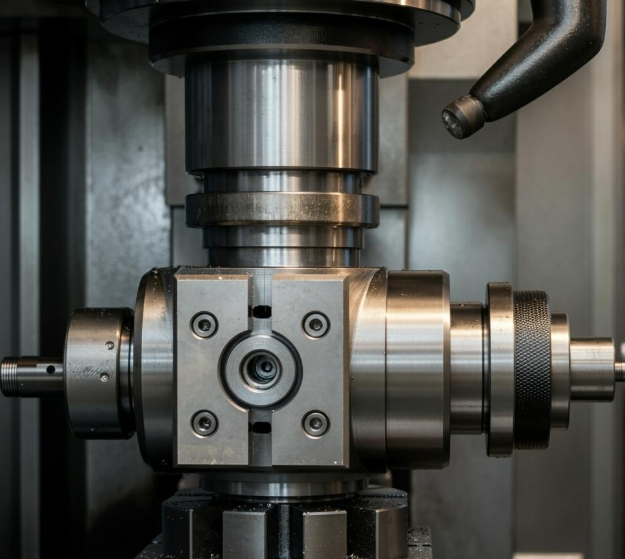

In an era where manufacturing precision can mean the difference between market leadership and obsolescence, precision machining has emerged as the defining force behind industrial innovation and quality control. As we navigate through 2025, this technological cornerstone continues to reshape manufacturing landscapes across industries, from aerospace components measuring mere microns to medical devices requiring unparalleled accuracy. The evolution of precision machining represents more than just technological advancement—it embodies a fundamental shift in how we approach manufacturing challenges, quality standards, and production efficiency.

How Does Precision Machining Enhance Product Quality and Performance?

Tight Tolerances: Precision machining allows for the production of parts with very tight tolerances, ensuring that components fit together perfectly. This reduces the likelihood of assembly issues and enhances overall product reliability.

Surface Finish: High-quality machining techniques can produce superior surface finishes. Improved surface quality can reduce friction, wear, and corrosion, leading to longer-lasting components.

Material Utilization: Advanced machining processes can optimize material usage, minimizing waste. This not only improves cost efficiency but also allows for the use of higher-quality materials.

Consistency and Reproducibility: Precision machining processes are highly repeatable, ensuring that each part produced meets the same specifications. This consistency is vital for high-volume production and maintaining product quality over time.

How Does Precision Machining Drive Technological Innovation?

Precision machining drives technological innovation by enabling the creation of complex and intricate components that meet the demanding specifications of modern applications. By utilizing advanced techniques such as CNC machining and additive manufacturing, engineers can design and manufacture parts with enhanced performance characteristics, such as reduced weight and improved strength. This capability fosters innovation in various industries, including aerospace, automotive, and medical devices, as it allows for the exploration of new materials and designs that were previously unattainable. Additionally, the integration of automation and real-time data analytics in precision machining processes optimizes production efficiency and quality, further propelling technological advancements.

How Does Precision Machining Reduce Production Costs?

Reduced Material Waste: By using advanced technologies like CNC machining or 3D printing, precision manufacturing ensures that materials are cut or formed with minimal waste. This leads to cost savings as less material is required to produce the final product.

Improved Efficiency: High-precision processes are typically faster and more efficient, reducing the time spent on production. This translates to lower labor costs and faster turnaround times, allowing for more products to be manufactured in less time.

Higher Quality and Fewer Defects: Precision manufacturing results in fewer defects or errors during production, leading to higher product quality. This reduces the need for costly rework, scrap, and returns, ultimately saving money in the long run.

Automation and Technology Integration: With the integration of automated systems and robotics in precision manufacturing, human labor can be minimized, and consistency is improved. This reduces the overall labor cost and the potential for human error.

Longer Lifespan of Equipment: High-precision machinery is often built for durability and efficiency. The long-term reliability of precision equipment means less frequent maintenance or replacement, thus lowering operational costs over time.

Supply Chain Optimization: Precision manufacturing helps in better alignment of supply chain management. By producing components that meet exact specifications, it ensures that parts fit together properly in the final product, reducing assembly time and costs.

How Precision Machining Drives Industrial Upgrading?

As a core technology in advanced manufacturing, precision machining significantly drives industrial upgrading by improving processing accuracy, surface quality, and product consistency. It not only meets the stringent requirements for components in high-end manufacturing industries such as aerospace, medical devices, and semiconductors but also promotes the transformation of traditional manufacturing toward intelligence and digitalization. Through the adoption of high-precision CNC equipment, advanced measurement technology, and intelligent production systems, precision machining has improved production efficiency, reduced costs, and enhanced product competitiveness. Meanwhile, it drives processing technology innovation, promotes coordinated development of related industrial chains, and facilitates manufacturing’s climb up the value chain. This technological progress not only improves product quality and added value but also drives the improvement of manufacturing process levels across the entire industry, ultimately achieving industrial structure optimization and transformation upgrading.

How Does Precision Machining Accelerate Intelligence and Automation Trends?

Precision manufacturing accelerates the trend toward smart and automated production by integrating advanced technologies like robotics, AI, and IoT. These technologies enable real-time monitoring, automated adjustments, and improved precision, reducing the need for human intervention. Automation streamlines processes, enhances efficiency, and ensures consistent quality, driving faster and more cost-effective production. Additionally, smart machines can optimize workflows, predict maintenance needs, and adapt to changes in real-time, further advancing the shift toward intelligent manufacturing.

Comparative Table of Precision Machining Benefits

| Aspect | Traditional Manufacturing | Precision Manufacturing |

|---|---|---|

| Accuracy | ±0.1mm typical tolerance | ±0.001mm or better |

| Quality Control | Manual inspection | Automated real-time monitoring |

| Production Speed | Lower throughput | High-speed production |

| Waste Rate | 5-10% typical | Less than 1% |

| Automation Level | Limited automation | Fully automated processes |

| Cost Efficiency | Higher labor costs | Reduced long-term costs |

| Innovation Potential | Limited by manual processes | Enables complex designs |

| Quality Consistency | Variable | Highly consistent |

| Material Optimization | Limited control | Precise material usage |

| Production Flexibility | Less adaptable | Highly adaptable |