-

With the increasing demand for precision and functional parts in the manufacturing industry, surface treatment of CNC-machined custom parts has become an indispensable link. It can not only improve the performance of parts but also optimize their appearance. However, the cost and cycle of surface treatment vary depending on many factors. How to make a reasonable choice is directly related to the efficiency and cost control of the project. The importance of surface treatment CNC machined parts usually have extremely high dimensional accuracy and complex geometric structures, but......

2024.12.6Published by kenRead More -

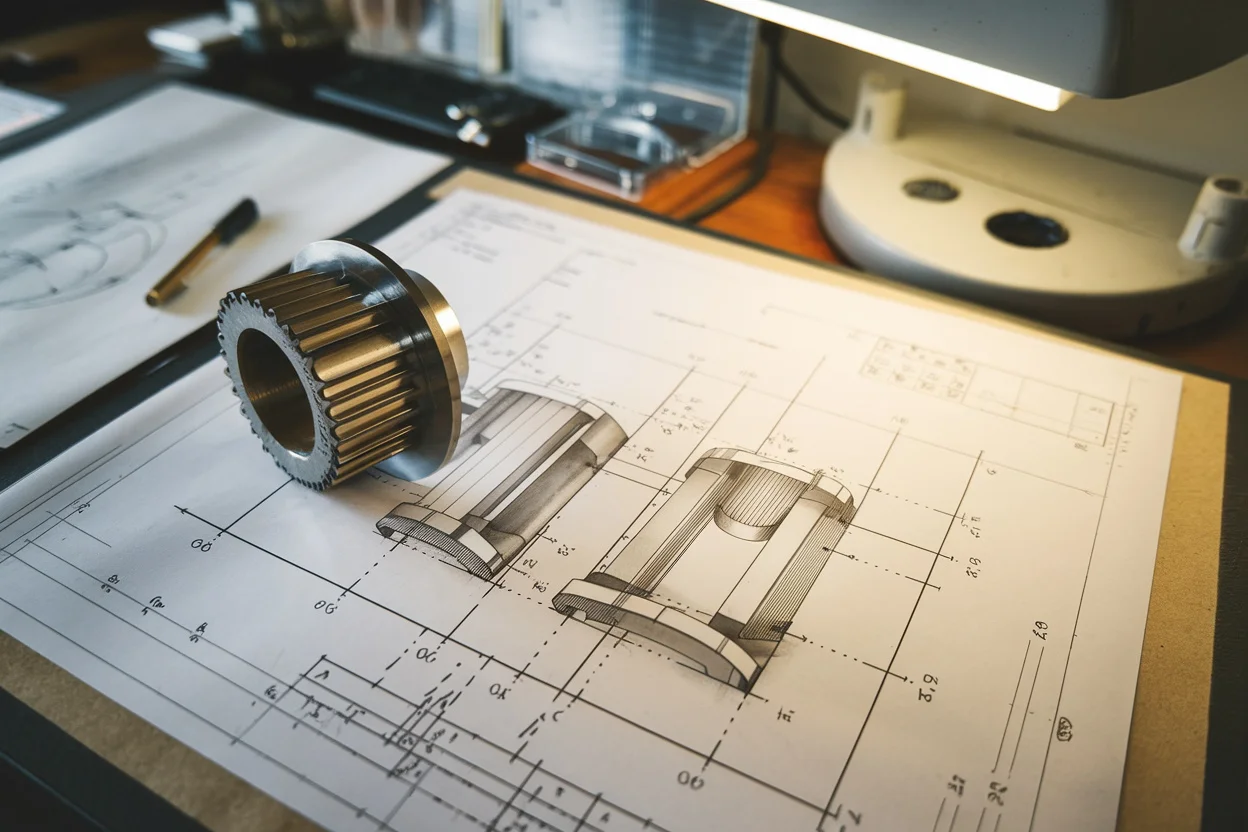

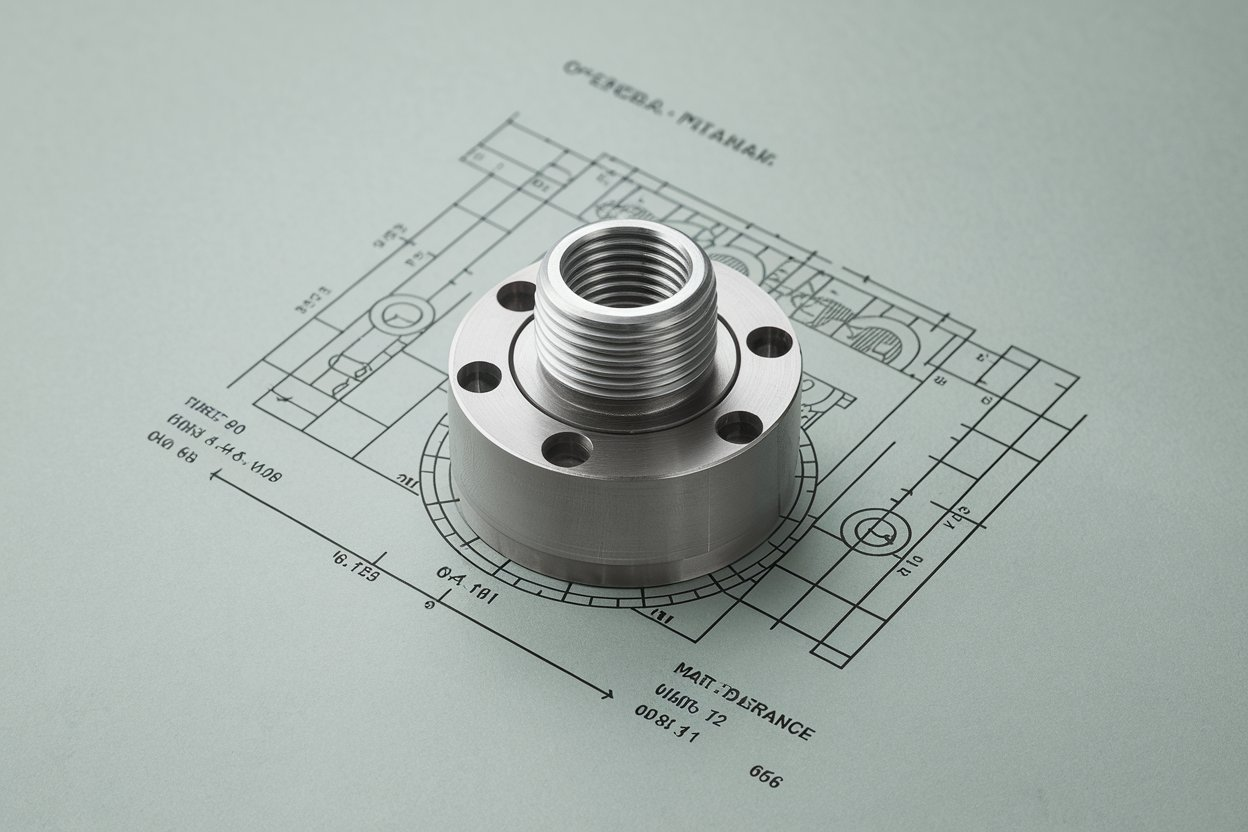

When customizing machined parts, detailed and standardized technical drawings are required so that the processing plant can accurately understand and manufacture the parts. These drawings should include the following: 1. Part view Main view, top view, side view: show the main appearance and structure of the part as needed. Sectional view and partial enlargement: used to express internal structure or details, such as holes, slots or complex geometric shapes. 2. Dimensioning Overall dimensions: clarify the overall length, width and height of the part. Key part di......

2024.12.6Published by LucasRead More -

Custom CNC machining has become a cornerstone in modern manufacturing, offering precision, flexibility, and efficiency. Manufacturers of custom CNC parts not only focus on the production process but also invest heavily in pre-sales and after-sales services. These services are critical for ensuring customer satisfaction, building long-term relationships, and maintaining a competitive edge. This is also a necessary condition for being a top CNC machining service provider in China. CNCJY provides the following services: Pre-Sales Process The pre-sales process is the foundation......

2024.12.3Published by LucasRead More -

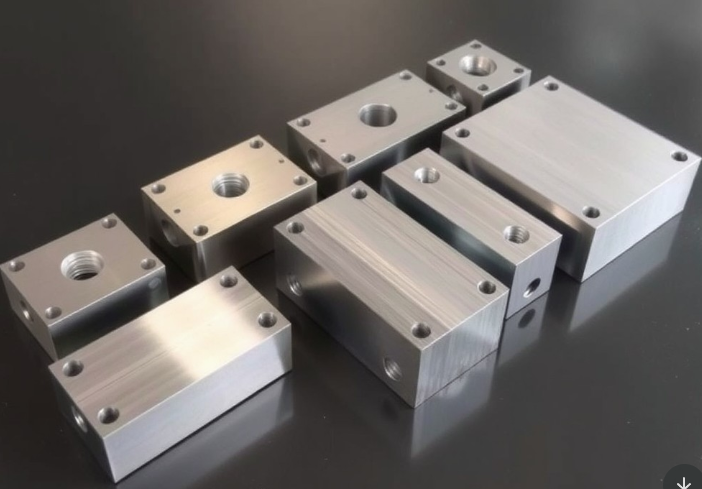

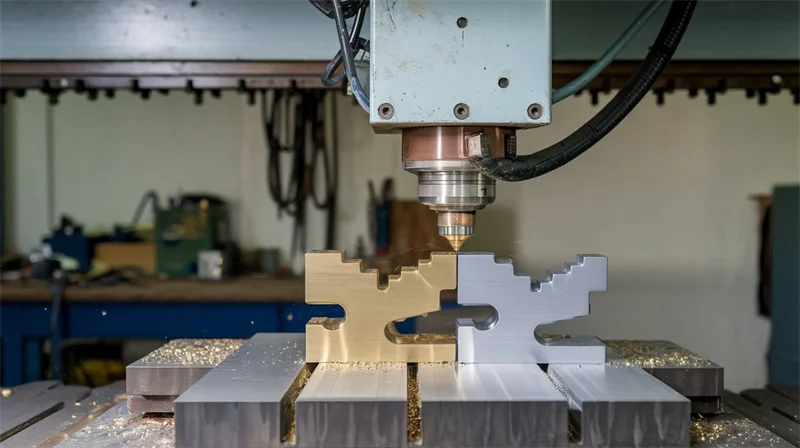

Aluminum CNC machining is a precise and versatile process used to create custom parts for industries like aerospace, automotive, and consumer electronics. By combining advanced technologies and refined techniques, this process ensures high-quality results. Below is an in-depth explanation of the steps and considerations involved in manufacturing aluminum parts through CNC machining. Aluminum CNC Machining Process1. Designing and ProgrammingThe initial stage of CNC machining involves creating a digital blueprint of the part using C......

2024.11.26Published by @WCYRead More -

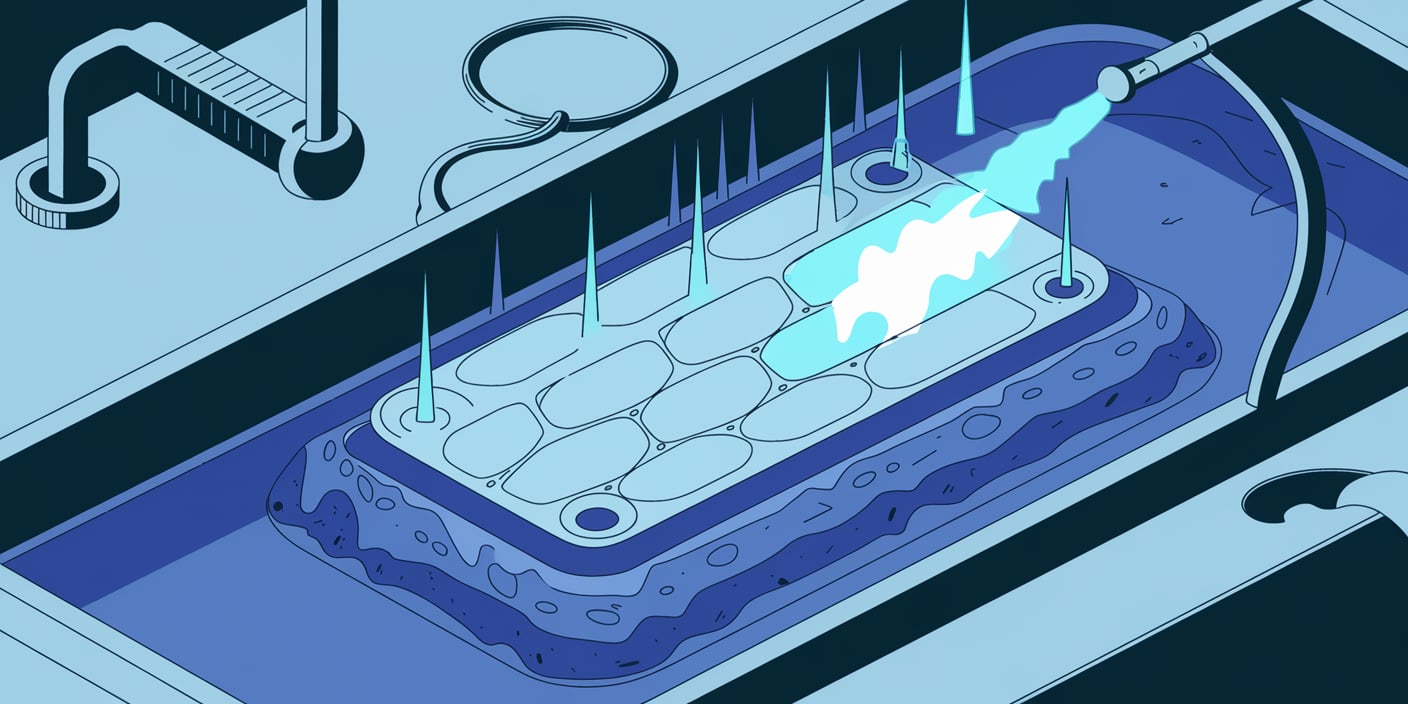

Principles of Anodizing Treatment The principle of anodizing treatment is to use an aluminum alloy as the anode and a metal or non-metal as the cathode in an electrolyte solution. Through the action of electric current, a layer of aluminum oxide film is formed on the surface of the aluminum alloy. This aluminum oxide film has high hardness, wear resistance, and corrosion resistance, which protects the aluminum alloy from external environmental influences. Characteristics of Anodizing Treatment 1. Improved Wear Resistance Anodizing treatment significantly enhances the wear resistance o......

2024.11.26Published by LucasRead More -

Ceramics, renowned for their hardness, heat resistance, and chemical inertness, play a vital role in a wide range of industries, how to manufacture ceramic parts, and how to get the best results? This article will focus on ceramic machining, exploring the production methods, application fields, materials, challenges & measures, milling strategies, and cutting-edge tools that enable the precise shaping of these demanding materials. Ceramic Machining Processes and Techniques Ceramic Grinding Ceramic grinding is a machining process that utilizes ceramic abrasives or dia......

2024.11.11Published by @LJCRead More -

Precision CNC machining has very wide applications in the manufacturing of medical components. This machining technology enables rapid production of complex medical parts, with production cycles that can be completed within a few hours. It is capable of fabricating not only surgical instruments but also critical medical devices and implants. The machining requires extremely high precision and repeatability to meet the demands of surgery, optical instruments or their maintenance and repair. Why Precision Is Important In Medical Parts Manufacturing? Precision is crucial in medical......

2024.10.18Published by @WCYRead More -

Best brass and aluminium grades for CNC machining In CNC machining, choosing the right material grade is crucial to the success of the project. Different materials have different mechanical properties, machining difficulty and cost, which will directly affect the quality and production efficiency of the final product. Specific introduction to the characteristics of common brass grades such as 360 brass and 385 brass, and aluminum grades 6061, 7075 and 2024 aluminum. Point out their advantages and disadvantages in rolling and milling processes, so as to help readers choose the bes......

2024.10.17Published by kenRead More