-

ABS generally refers to ABS plastic, which is a terpolymer of acrylonitrile (A), butadiene (B) and styrene (S). The relative content of the three monomers can be changed at will to make various resins. ABS has the common properties of three components. A makes it resistant to chemical corrosion and heat, and has a certain surface hardness. B makes it have high elasticity and toughness. S makes it have the processing and molding properties of thermoplastic plastics and improves electrical properties. Therefore, ABS plastic is a “tough, hard and rigid” material with easy ac......

2022.9.30Published by @WLPRead More -

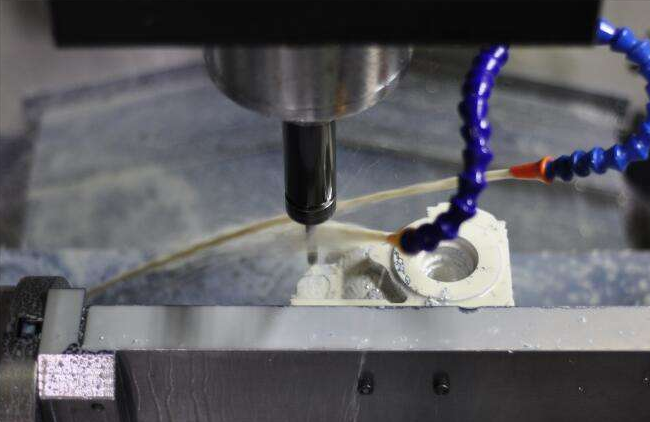

CNC machines are the most common manufacturing machinery equipment in the manufacturing industry, and the machining performance of CNC machine is widely used. In the use of CNC machine, its processing personnel need to master some detailed knowledge. The following is a detailed analysis the process of preparing a CNC machine. CNC machines usually do not need special process equipment such as special fixtures. When replacing the workpiece, it is only necessary to call the program to install the tool and adjust the tool data of the CNC machine stored in the CNC device, which greatly sh......

2022.9.30Published by @WLPRead More -

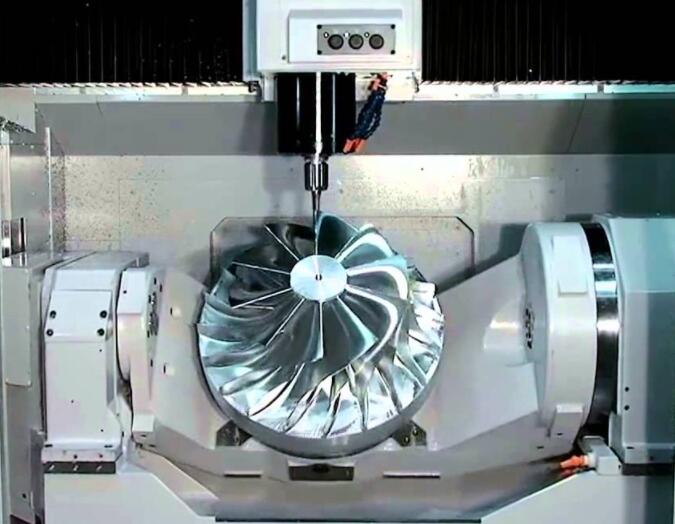

In the process of CNC milling, the cutting tool moves perpendicular to its axis, so it can remove excess materials from the workpiece around the tool. To manufacture milling parts of various shapes and sizes, many types of milling cutters are required. 9 Types of Milling Cutters - What Are the Different Types of Cutting Tools in CNC Milling ......

2022.9.30Published by @LJCRead More -

Aluminum is the most typical alloy used in anodizing, even though other non-ferrous metals can also be anodized, anodized aluminum products are widely used due to their great properties and performance. In this article, we are going to go over the advantages and applications of anodized aluminum plates. Advantages of Anodized Aluminum Plates ......

2022.9.30Published by @LJCRead More -

Hard anodizing is the process of functionally refining aluminum components by using the anode in a specific cold electrolyte. The process of hard aluminum anodizing results in the formation of conversion coatings that are extremely thin and non-metallic. In this article, we’ll take a look at an overview of the hard anodizing of aluminum, including the properties of the hard anodized coating, the characteristics of different aluminum alloys, and some differences between hard anodizing and regular anodizing. ......

2022.9.30Published by @LJCRead More -

Aluminum alloy parts and products are preferred by many industries because of their lightweight and good appearance. CNC aluminum machining is one of the best production methods for aluminum alloy shell products. What tools should be selected and what should you know during the machining process? Cutting Tool Selection in CNC Machining of Aluminum Cases ......

2022.9.30Published by @LJCRead More -

A machining center is a kind of CNC machine tool. What is a CNC machining center? And what are the different types of machining centers? Today we’ll dive into its classification. What is a Machine Tool? Turning, milling, planing, grinding, boring, drilling, and more operations are all mechanica......

2022.9.30Published by @LJCRead More -

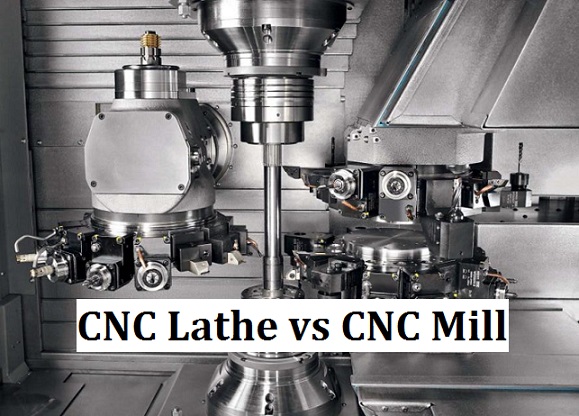

CNC lathes and CNC mills are both commonly used equipment for machining, but process materials in different ways. What is the difference between a lathe and a milling machine? And which one should you choose? What is a Lathe? A lathe makes cylindrical parts by rotating material on a stationary tool. ......

2022.9.30Published by @LJCRead More