-

The mechanical keyboard is loved by young people because of its excellent feel and quality. The mechanical keyboard has a longer service life than the ordinary membrane keyboard, which is about 10-20 years with proper maintenance. The mechanical keyboard is easy to realize the function of full keyboard keys without conflict. Mechanical keyboard has high playability. Of course, everything has two sides. Mechanical keyboards are expensive, waterproof and heavy. Although the mechanical keyboard has shortcomings, it does not prevent y......

2022.10.25Published by @WLPRead More -

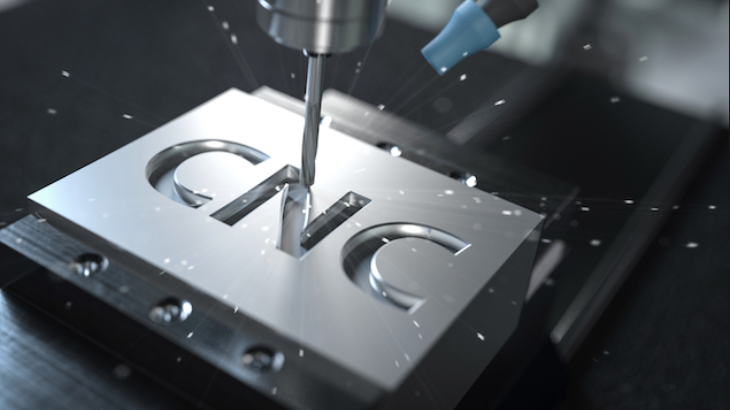

When designing a part, it is best to think ahead of time about which process will be used to manufacture the model and optimize accordingly for that production process. Among them, the most common processing methods of plastic parts are CNC processing and injection molding. So how do we choose between these two processes? Plastic CNC VS Plastic Injection Molding CNC Machining CNC machining usually starts with a piece of material, and after several removals of the material, a set shape is obtained. CNC plastic processing is one of the main ways of making prototypes at present, mainly pro......

2022.10.24Published by @ZNRead More -

Because of their high security and convenience, smart locks have begun to enter the whole family and become the smart choice for many families. However, the residual fingerprints on the smart lock panel are a headache for users. Once the fingerprints remain, the panel will be dirty. It must be cleaned regularly, and secondly, leaving your fingerprints exposed will always make people feel unsafe. In response to this situation, some smart lock manufacturers have begun to use CNC engraving technology, which not only makes the locks more beautiful and elegant but also ensures that there is ......

2022.10.21Published by @ZNRead More -

Reduced manufacturing costs are frequently the primary objective in CNC processing, whether you want to build a single prototype or prepare for mass production. Fortunately, as a designer, your selection will have a significant impact on the final cost. You may produce optimized components while minimizing costs and meeting design criteria by using the “Design for Machinability” approach described in this article. What factors influence the price of CNC parts? The cost of CNC machined parts is determined by the following factors:Processing time: The longer it takes......

2022.10.21Published by @WCYRead More -

In this day and age, when user experience is very important, more and more phone, laptop, and wearable device makers are putting effort into the shell materials. Just in the field of mobile phones, engineering plastics are slowly being replaced by metals for the casings of phones. Throughout the history of mobile phone shells, there have been a lot of different combinations, like plastic and metal, glass and metal, all plastic, all glass, etc., but none of them have been as popular as all metal materials. The all-metal mobile phone is better to touch in many ways, and it looks and feels......

2022.10.21Published by @ZNRead More -

When developing components using numerous technical polymers (such as PVC, POM, PEI, or PEEK), 3D printing is not possible. There is no dependable and cost-effective printing formula for these polymers. However, CNC plastic processing allows you to simply design any form of plastic based on the customer’s needs. Special materials for 3D printing are often expensive, and production costs are depending on the amount of materials used, implying that the cost of larger or more pieces is greater, but CNC processing plastic is a more convenient and cost-saving procedure. Following that,......

2022.10.21Published by @WCYRead More -

Aluminum alloy materials are the most used materials in CNC machining. In order to overcome the defects of surface hardness and wear resistance of aluminum alloy parts, expand the scope of application, and prolong the service life of aluminum alloy parts, surface treatment technology has become a part of the CNC machining of aluminum alloys. An indispensable part and anodizing technology are widely used and mature. After anodizing the surface of aluminum alloy accessories, their functionality and decoration can be enhanced. Anodizing can achieve any color except white, and can also achi......

2022.10.21Published by @ZNRead More -

For computer enthusiasts, the metal texture of the mechanical keyboard and the sound of the mechanical equipment are a kind of enjoyment for keyboard users. The modeling design of the mechanical keyboard frame is one of my favorite hardware configurations, especially the glaze color, which is very intoxicated when the computer is typing. Nowadays, DIY keyboard has become a great pleasure for computer enthusiasts, and preference for design schemes is becoming more and more important. Sometimes, it is a headache to choose a suitable......

2022.10.20Published by @WLPRead More