-

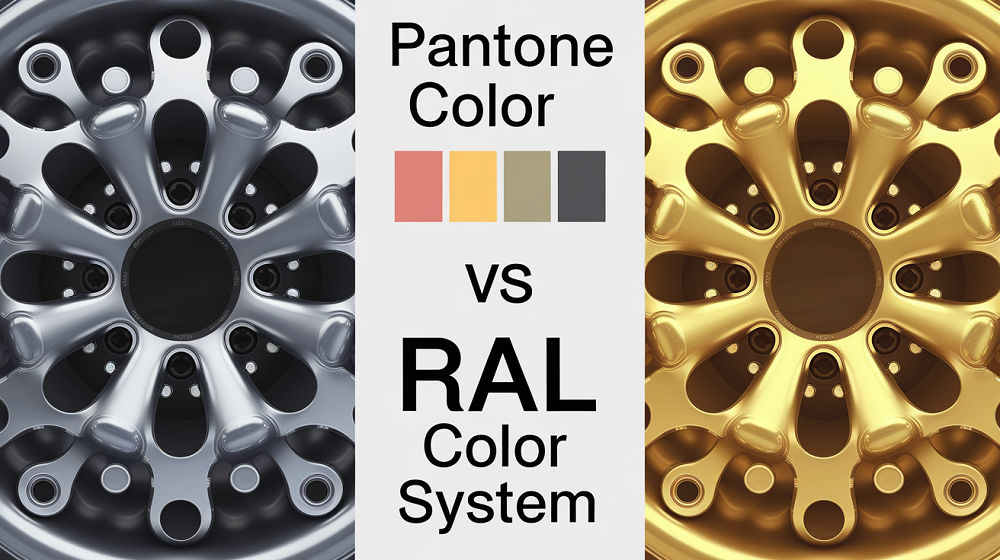

Choosing the right color system is essential in ensuring that precision components meet both functional and aesthetic requirements. Through anodizing, manufacturers can create durable and visually appealing finishes for aluminum parts. Among the most widely used color systems in anodizing are RAL and Pantone. Each system offers unique benefits and serves specific needs. Here we examine the differences between these two systems and their role in precision component manufacturing. 1. Anodizing in Precision Components Anodizing is an electrochemical process that enhances the s......

2025.1.3Published by YLRead More -

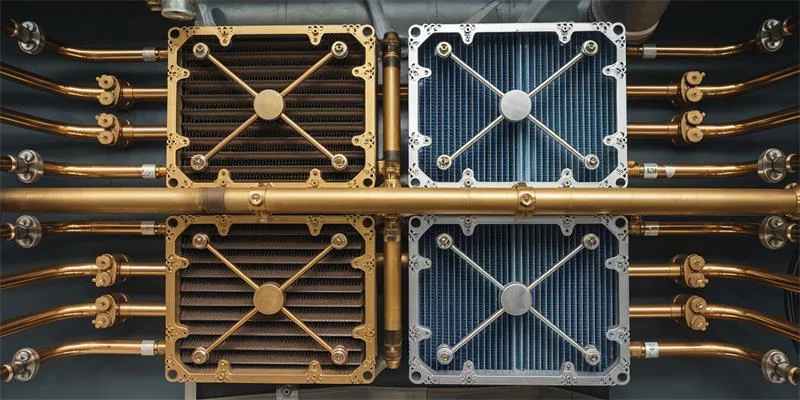

When it comes to choosing the perfect radiator for your vehicle or industrial application, the debate often narrows down to two contenders: brass and aluminum. Each material has its unique strengths, and understanding these can help you make an informed decision. In this blog, we’ll break down the differences, pros, and cons of brass and aluminum radiators while focusing on what truly matters to you as a customer. Why Material Matters Radiators are critical for efficient cooling. The choice of material impacts: Heat Dissipation Efficiency: How well the radiator cools ......

2024.12.24Published by kenRead More -

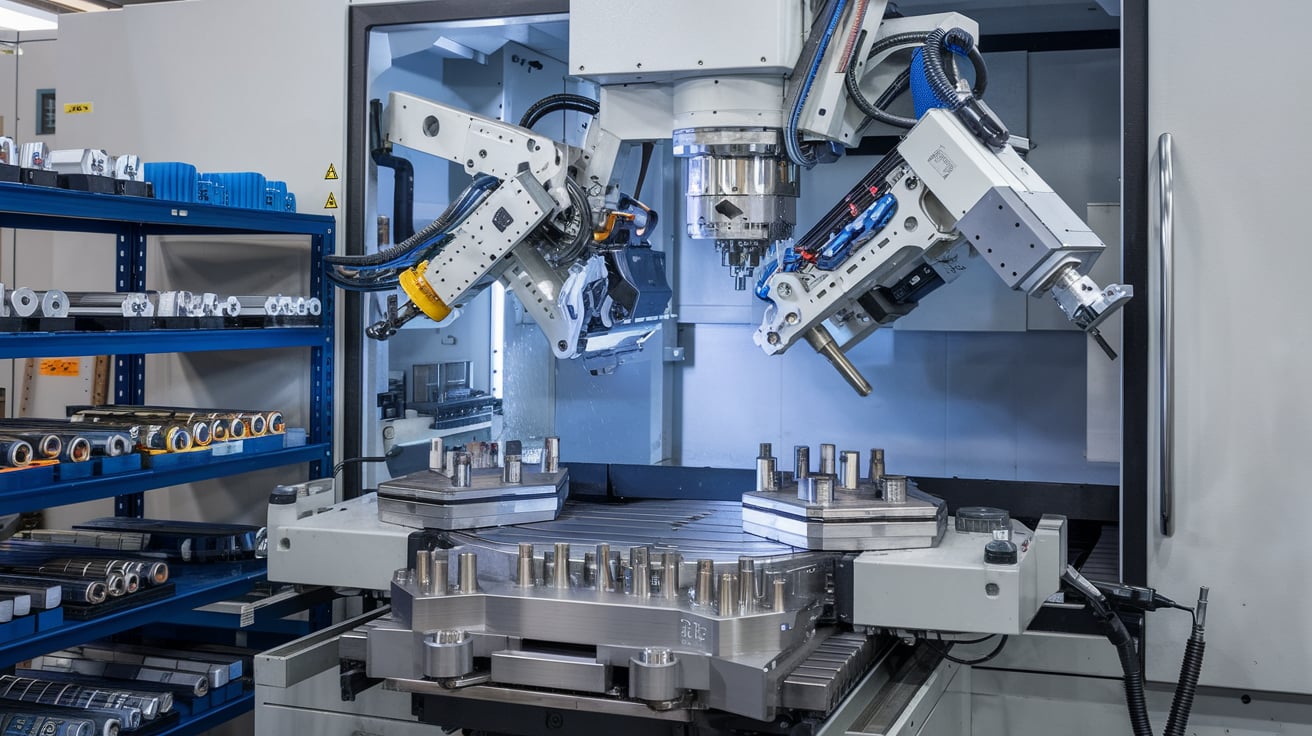

In today’s highly competitive manufacturing landscape, the demand for intricate, high-precision components is at an all-time high. Industries like aerospace, automotive, medical, and energy rely on cutting-edge technology to push the boundaries of innovation. Enter multi-axis five-axis machining—a game-changer that transforms how we design and produce complex parts. What Is Five-Axis Machining? At its core, five-axis machining refers to a CNC (Computer Numerical Control) system that moves a tool or part along five different axes simultaneously. While traditional three-axis machine......

2024.12.23Published by LSRead More -

In today’s world of precision engineering, the demand for manufacturing processes that can create intricate, high-tolerance parts is growing rapidly. One technology that stands out in this arena is electrical discharge machining (EDM). Known for its ability to handle complex designs and hard materials, EDM is a cornerstone of modern manufacturing, playing a critical role in industries like aerospace, automotive, and medical devices. But what makes EDM so effective? Let’s explore how this innovative process is shaping the future of manufacturing. What is electrical discharge mac......

2024.12.23Published by kenRead More -

In today’s manufacturing world, where precision and speed matter more than ever, laser cutting has become a game-changer. It’s not just about cutting materials; it’s about doing it accurately and efficiently that other methods can’t match. From metal parts for machinery to sleek designs for decorative projects, laser cutting has found its way into almost every industry, and it’s easy to see why. Learn more Laser cutting works by focusing a powerful beam of light onto a material, cutting through it with incredible precision. Imagine slicing through metal or wood with ......

2024.12.16Published by kenRead More -

CNC Machining Parts: Understanding the Role of Material Hardness in Precision Manufacturing CNC machining is at the heart of modern manufacturing, delivering precision, efficiency, and versatility across countless industries. One critical factor determining the quality and performance of machined parts is material hardness. Whether you’re working with metals, plastics, or composites, understanding and managing hardness is essential for achieving optimal machining results. In this article, we’ll explore how material hardness influences CNC machining processes, its challenge......

2024.12.13Published by kenRead More -

The Art of CNC Machining: Mastering Chamfers and Fillets (R Corners) In CNC machining, seemingly minor details like chamfers and fillets (commonly referred to as R corners) play a pivotal role in enhancing functionality, safety, aesthetics, and durability. These subtle design elements are integral to achieving precision engineering and product optimization. This blog delves into what chamfers and R corners are, their significance, the processes behind their creation, and their evolving applications in various industries. What Are Chamfers and Fillets? Chamfers are beveled ......

2024.12.12Published by LSRead More -

In the realm of CNC machining, customization of chamfers and fillets (R corners) has become a critical focus for industries striving to meet unique product requirements. Tailoring these features goes beyond standard practices, opening the door to innovative designs and enhanced performance for components across diverse applications. This article explores how CNC machining enables precise customization of chamfers and fillets, delves into the techniques used, and highlights their importance in various sectors. Why Customize Chamfers and Fillets? 1. Industry-Specific Requir......

2024.12.12Published by LucasRead More