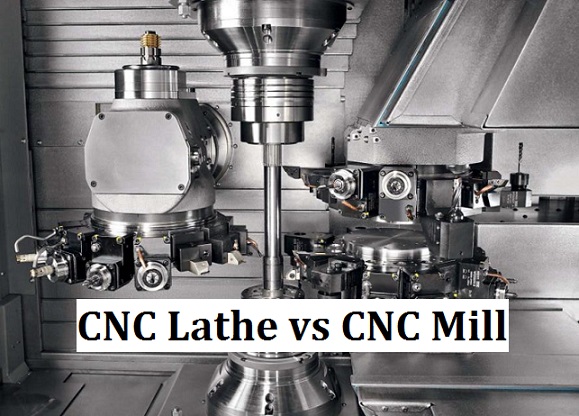

CNC lathes and CNC mills are both commonly used equipment for machining, but process materials in different ways. What is the difference between a lathe and a milling machine? And which one should you choose?

What is a Lathe?

A lathe makes cylindrical parts by rotating material on a stationary tool. Using a lathe to make parts is called turning. The raw material is fixed in a high-speed rotating chuck – the rotating axis is called the C-axis. The tool of the lathe is mounted on a tool holder, which can move parallel to the C-axis (represented by movement along the Z-axis) and perpendicular to the C-axis (X-axis movement). On the CNC lathe, controlling the X and Z positions of the tool rest at the same time, it is possible to change the speed of some features and turn complex cylindrical geometry. Some advanced lathes have automatic tool changers, part catchers for serialized production, and power tools that allow certain milling functions.

What is a Mill?

Unlike a lathe, a mill or milling machine holds the material in a fixture and uses a rotating tool to cut it. CNC milling machines can simultaneously control movement along these axes to create complex geometry, such as surfaces. This main type of milling machine is called a 3-axis milling machine. A 5-axis milling machine can cut more complex parts and can process a wide range of parts, including many different functions that cannot work on the lathe. On the other hand, the setup and programming of the milling machine can be complex.

What Are the Differences Between CNC Lathe and Milling Machine

The biggest difference between a lathe and a mill would be the rotation of the part and cutting tool, they also differ in the structures, parts, operations, and more.

1. Different structures

The lathe is a fixed vertical horizontal tool moving machining circle and surface with the rotary tool of the workpiece. The milling machine is used to fix the blank and clamp the parts on the machine tool spindle through a three-grip chuck.

2. Different rotations

The lathe is the movement of parts around the axis and the cutter around the axis, while a milling machine is used to fix the workpiece and process parts through the moving fixture and milling cutter.

3. Different parts

The lathe can be used to process various internal and external cylindrical surfaces, internal and external conical surfaces, internal and external threads, end faces, grooves, knurling, etc. The milling machine can process flat surfaces, such as horizontal and vertical planes, grooves (keyway, T-shaped groove, dovetail groove, etc.), gear, spline shaft, sprocket, spiral surface (thread, spiral groove), and various curved surfaces.

Should You Select a Milling Machine and Lathe?

Which one should be selected for CNC machining? Consider its own advantages and the requirements of the workpiece to be processed. Overall, the lathe is most suitable for manufacturing cylindrical parts. The cross-section of the parts must be circular, and the same central shaft must run through its entire length. The milling machine can process cylindrical features, but if the part is purely cylindrical, the lathe is a better and more accurate choice. More sophisticated machines, such as Swiss lathes, can cut planar features and drill vertical holes in the material. However, these machines are still more suitable for cylindrical parts.