When it comes to choosing the perfect radiator for your vehicle or industrial application, the debate often narrows down to two contenders: brass and aluminum. Each material has its unique strengths, and understanding these can help you make an informed decision. In this blog, we’ll break down the differences, pros, and cons of brass and aluminum radiators while focusing on what truly matters to you as a customer.

Why Material Matters

Radiators are critical for efficient cooling. The choice of material impacts:

Heat Dissipation Efficiency: How well the radiator cools your system.

Durability: Resistance to wear, corrosion, and damage.

Weight: Impact on vehicle performance or system mobility.

Cost: Upfront price and long-term maintenance.

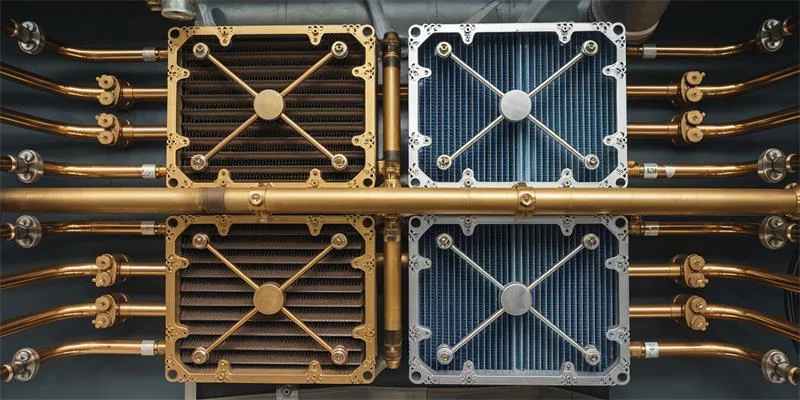

Comparing Brass and Aluminum Radiators

Let’s dive into a side-by-side comparison to understand their differences:

| Aspect | Brass Radiators | Aluminum Radiators |

|---|---|---|

| Heat Transfer | Excellent heat conduction; ideal for extreme environments. | Good heat dissipation; lightweight design aids airflow. |

| Durability | Highly durable and repairable; resistant to rust. | Corrosion-resistant with protective coatings but harder to repair. |

| Weight | Heavier; can affect vehicleperformance. | Lightweight; enhances performance in racing or mobility-focused applications. |

| Cost | Higher initial cost; longer lifespan offsets expenses. | More affordable upfront; may require earlier replacement. |

| Customization | Easy to repair and maintain. | Limited customization; built for efficiency and mass production. |

| Maintenance | Easy to repair and maintain. | Difficult to repair; replacement is often required. |

Who Should Choose Brass Radiators?

Ideal for Heavy-Duty Applications:

Trucks, tractors, and heavy machinery where durability and reliability are non-negotiable.

Industrial systems in harsh environments, such as mining or construction.

Why Brass Works: Brass radiators are known for their exceptional strength and heat conduction properties. Their resistance to corrosion and ability to be repaired multiple times make them a long-term investment for applications where downtime is costly.

Who Should Choose Aluminum Radiators?

Perfect for Performance Enthusiasts:

Racing vehicles, sports cars, and motorcycles.

Lightweight industrial machinery or mobile systems.

Why Aluminum Excels: Aluminum radiators are lightweight and cost-effective, making them an excellent choice for performance-driven applications. They reduce overall vehicle weight, contributing to faster speeds and better fuel efficiency.

Breaking It Down by Customer Type

For Automotive Enthusiasts:

If you own a classic car or heavy-duty truck, a brass radiator is your best bet for long-term reliability. On the other hand, if you’re looking to upgrade your sports car for better track performance, an aluminium radiator’s lightweight design will give you an edge.

For Industrial Users:

Heavy machinery operators should consider brass radiators for their robustness and ease of maintenance. However, industries where weight savings matter—like aerospace or portable equipment manufacturing—may find aluminum radiators more appealing.

The Long-Term Cost Factor

While brass radiators might have a higher initial cost, their longer lifespan and reparability often make them more cost-effective in the long run. Aluminum radiators, however, save money upfront and are perfect for applications where performance and weight savings trump longevity.

Quick Decision Guide

| Question | Go for Brass | Go for Aluminum |

|---|---|---|

| Do you need maximum durability? | Yes | No |

| Is weight a critical factor? | No | Yes |

| Are you on a tight budget? | No | Yes |

| Will you need custom sizing? | Yes | No |

| Is it for a performance vehicle? | No | Yes |

Choosing between brass and aluminum radiators boils down to your specific needs and priorities. Whether you value long-term reliability, lightweight performance, or cost efficiency, each material has a niche it excels in.

Still unsure? Share your requirements with us, and we’ll help you choose the perfect radiator solution for your application. The right radiator isn’t just a cooling component—it’s an investment in performance and durability.