At present, with the rapid development of digital electronic products and the increasingly fierce market competition, consumers have particularly high requirements for “light and thin” 3C products. Therefore, the processing and manufacturing technology of 3C products needs to make breakthroughs in materials, processes and other aspects. Among 3C materials, magnesium alloy materials have become the new darling of raw materials.

First of all, in practical applications, magnesium alloy is the lightest, accounting for about two-thirds of aluminum and one quarter of iron, which meets the needs of users of “light and thin” 3C products. In addition, magnesium alloy also has higher specific strength, higher elastic modulus and better vibration damping, and is a structural member of 3C electronic products. The data shows that if ABS plastic is replaced with magnesium alloy, the weight of 3C products will be reduced by 36%, while the thickness will be reduced by 64%. Secondly, it has good heat dissipation performance. Magnesium alloy has 350~400 times higher thermal conductivity than ABS material. In the process of manufacturing high notebook keyboard case, magnesium alloy is used as the material. Generally, no cooling fan or cooling hole is required. Finally, it also shows excellent electromagnetic shielding performance. The shielding performance of magnesium alloy is better than that of aluminum alloy, and the shielding effect of electromagnetic wave is better, which is more suitable for manufacturing high-precision electronic products. It can also be used as the shell of computers, mobile phones and other electronic devices to generate electromagnetic radiation, thus reducing the harm of electromagnetic waves to the body.

Advantages of CNC Machining Technology of Magnesium Alloy in 3C Products

Magnesium alloy has the characteristics of flammability and corrosion in processing. Compared with traditional iron, aluminum and other metals, it is not suitable for processing. Therefore, in the early process of using magnesium alloy, more die casting and other processes are used. However, due to the continuous progress of 3C process, this molding method can no longer meet the requirements of the market. First of all, due to the improvement of the miniaturization and integration of 3C products, the shell structure of 3C products becomes more complex, and it is difficult to accurately process them by die casting, die casting and other processing technologies; Secondly, the development and manufacturing cycle of 3C products in China has been continuously shortened, and the mold opening cycle has become an important factor restricting the development cycle of 3C products. Finally, there is a great conflict between the zero tolerance of the consumer group to the appearance defects of the product and the appearance of the casting defects. Therefore, the application of numerical control technology in magnesium alloys has attracted increasing attention.

Discussion on Safety of Magnesium Alloy in CNC Machining of Notebook Computer Case

In general, magnesium alloys are dangerous and belong to unsafe materials. For the CNC processing of magnesium alloy, the first step is to ensure its safety, which is the prerequisite and standard for the next step of processing and manufacturing. However, based on his years of practical experience and theoretical analysis, the author concluded that in practical work, magnesium alloy block solid material is very safe and will not explode and burn. Even if magnesium rod is directly heated and burned in the flame, it is difficult to make magnesium burn. Even if the magnesium powder is ignited, as long as the ignition source is removed, the magnesium powder will quickly lose heat, and when its temperature is lower than the ignition point, it will automatically go out. Magnesium dust, debris, light and thin materials have certain combustion and explosion hazards. It is generally believed that explosion will occur when the content of magnesium powder in the atmosphere exceeds 20 mg/L; When magnesium powder is directly heated to 340~560 ℃, it will also cause combustion of magnesium powder. Therefore, how to effectively manage and control the dust and debris of magnesium alloy is the key to ensure the safety of magnesium alloy production. Therefore, in the production management of magnesium alloys, we should not “talk about magnesium discoloration”, or even dare to engage in the production of magnesium alloys, nor should we do it carelessly. As long as the strict and efficient production management of magnesium alloy is carried out, the production safety of magnesium alloy can be ensured.

Research on CNC Machining Technology of Magnesium Alloy Notebook Computer Keyboard Case

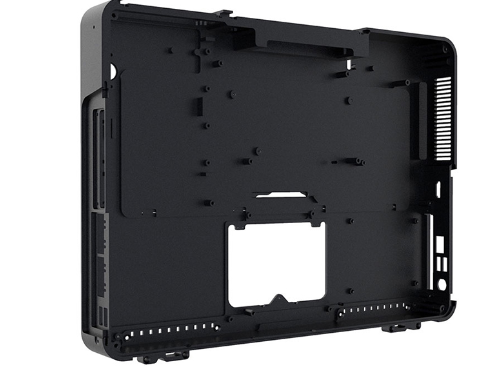

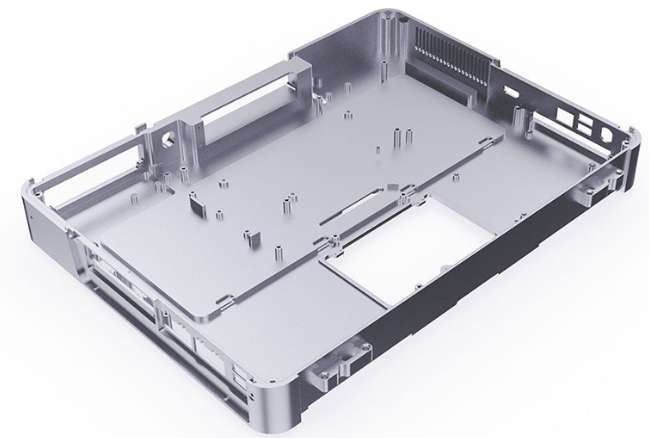

(1) As shown in Figure 1, due to its complex structure and high dimensional accuracy, the whole numerical milling process is adopted for molding. In terms of cutting tools, cutting parameters, cutting schemes, selection of cutting fluid, corrosion measures, chip treatment and other aspects, the magnesium alloy cutting process is significantly different from the traditional aluminum alloy processing process.

The cutting tool design principles for cutting steel and aluminum are also suitable for magnesium alloy cutting. Because magnesium alloy has lower cutting capacity and lower heat capacity, the number of teeth required for milling cutters using magnesium alloy is more than that of other metals. Reducing the number of sawteeth can improve the chip capacity and cutting capacity of the cutting fluid, reduce the wear heat, increase the chip capacity gap, reduce the distortion of the saw blade, reduce the power consumption and improve the heating efficiency. In the production of magnesium alloy, three-piece cemented carbide end milling cutter is usually selected. Under some specific conditions, such as insufficient blade length and inappropriate size of three-edge cutters, four-edge carbide end mills can also be used.

(2) The tool is made of magnesium alloy with good thermal conductivity, soft material and low cutting force, so it can dissipate heat quickly during processing, reduce the number of blades, and prolong the service life of the tool. However, the magnesium alloy cutting tool must have sharp blade, because the wear of the blade will increase the friction during cutting, make the cutting temperature rise sharply, make the magnesium sheet flash and burn, and increase the unsafe factors during cutting. Therefore, in magnesium alloy cnc machining, it is usually necessary to select new hard materials.

(3) The cutting fluid is made of soft and easy-to-cut magnesium alloy material. Whether the cutting fluid is used or not, a very smooth machining surface can be obtained.

The dry method can reduce the treatment cost without cutting fluid, and the waste is easy to collect, store and transport. Therefore, dry process is recommended in many literatures. However, when fine chips are generated at high speed, the dry method may cause fire. This requires the CNC operator to pay close attention to the processing process and put out the fire immediately in case of fire, but this method still has great risks. This limits the ability of operators to operate multiple machines at the same time, which is not worth it in terms of overall production cost and efficiency.

In addition, magnesium alloy is easy to expand at high temperature. According to the data, the linear expansion coefficient of magnesium alloy is 26.6~27.4 μ m/(m. C) at 20~200 ℃. For example, in the length range of 200 mm, if the temperature rises by 10 degrees Celsius during processing, it will cause a processing error of 0.053-0.0548 mm. Therefore, without the use of cutting fluid for cooling, the machining accuracy of magnesium alloy parts has been affected due to the rapid rise of temperature. This notebook case has a high requirement for dimensional accuracy, and the influence of this temperature cannot be ignored.

(4) Cutting parameter selection The machining parameters of CNC milling machine include: spindle speed, feed speed, tool cutting depth, and tool width.

A new type of magnesium alloy processing equipment is selected. Its theoretical high speed can reach 8000 rpm, the maximum feed speed is 15 m/min, and the processing accuracy is 0.01 mm. If the machine is used for a long time, its maximum speed will have a negative impact on the machine. Rapid feeding can not only save a lot of time, but also greatly improve product quality and failure probability. Therefore, we choose the method of large cutting depth and small feed to determine the cutting parameters.

After many years of CNC machining, we found that the speed and feed rate of the cutting parameters of the carbide end milling cutter have a certain impact when processing various materials, while the cutting depth and cutting width will not change much: during rough machining, the recommended cutting width is 50%~100% D (D is the tool diameter), and the cutting depth is 0.3~0.5 D. During finishing, the recommended width is 0.1-0.5mm and the depth is 0.5-1 D.

In the formulation of processing strategy, there is no significant difference between the processing methods of magnesium alloy and ordinary aluminum alloy processing materials, but in the finishing allowance, a gap of no less than 0.2 mm should be selected as far as possible to prevent the generation of too fine sawdust and avoid the flash point in processing.

(5) Anti-corrosion treatment of magnesium alloy in CNC process

It is generally believed that magnesium alloys have relatively active chemical properties and are prone to corrosion, especially after using the “wet” process, magnesium alloy parts contaminated by cutting fluid are more vulnerable to corrosion. In fact, according to our work experience, as long as appropriate anti-corrosion measures are taken, the structural strength and surface roughness of magnesium alloy will not be greatly corroded in a short time.

In order to reduce the corrosion of magnesium alloy, we have adopted the following methods:

① In the CNC process, the processing of magnesium alloy must be carried out continuously. It is not allowed to put the workpiece stained with cutting fluid on the workbench for a long time, and it is not allowed to stay overnight.

② Wash the processed magnesium alloy parts with clean water to maximize the residual amount of cutting fluid.

③ Dry the cleaned magnesium alloy parts quickly with a high-pressure air gun, and then wipe them with clean gauze.

④ Place the processed parts in the foam box, and do not contact other metals.

⑤ When the parts are stored or transported for a long time, they should be placed in dry bags, and the bag mouth should be folded down to ensure that the air in the bags is relatively non-ventilated.